Table of Contents

Even in today’s age, many organizations are still stuck with the ancient concept, “if it isn’t broken, don’t fix it.” This concept is now obsolete for modern organizations, and the new expression is, “if you don’t schedule maintenance for your equipment, your equipment will schedule it for you.” Organizations and businesses that are not scheduling maintenance for their pieces of equipment are stuck with corrective maintenance, witness much higher costs, frequent unexpected equipment breakdowns, lower efficiency, production downtime, and losses. In contrast, organizations focused on preventive maintenance enjoy several benefits. Let’s look at the top five preventive maintenance benefits that show why switching to modern maintenance management is crucial.

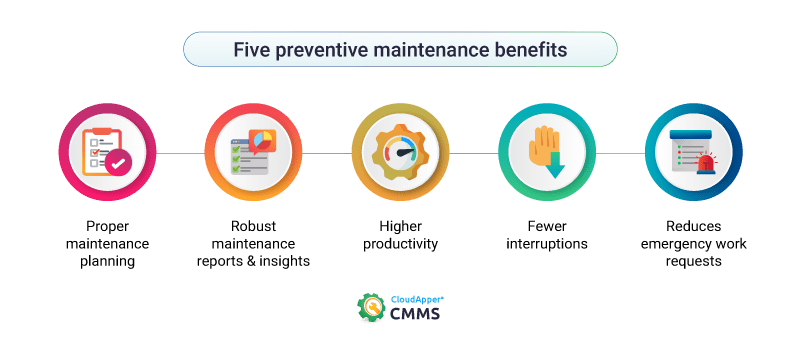

Five preventive maintenance benefits

Proper maintenance planning

One of the significant preventive maintenance benefits is helping plan maintenance management. During reactive maintenance, maintenance (repairs) are provided whenever necessary, something that’s entirely unplanned and can occur at any time. While emergency maintenance requests are present in preventive maintenance, these are far less common because the equipment gets regular maintenance compared to reactive maintenance.

With preventive maintenance, virtually everything is planned, including downtime. This helps maintenance managers take the assets offline safely when the equipment is not in use, reducing production disruptions. On the other hand, reactive maintenance and downtime are primarily unplanned, leading to higher costs and production disruptions.

Preventive maintenance also helps schedule maintenance tasks and inspections and assign technicians to them, helping keep everything organized and running smoothly. When everything is planned properly, costs can be effectively reduced, including preventive maintenance planning.

Robust maintenance reports and insights

Modern maintenance managers are well aware that providing regular maintenance isn’t enough. They must also use the information from the maintenance reports to identify discrepancies, strengths, and areas for improvement. For instance, which equipment is malfunctioning regularly even after receiving maintenance? Is any machine receiving too much maintenance? Are the machines receiving lubrication whenever necessary? These are crucial questions that maintenance managers can answer with the help of maintenance reporting and the insights they provide.

Higher productivity

Preventive maintenance means that the equipment is regularly receiving maintenance and inspections. This includes replacing spare parts, cleaning the machine, lubrication management, and much more. This keeps equipment working reliably, consistently, and efficiently, which leads to higher productivity, lower emergency maintenance requests, and lower production disruptions.

Fewer interruptions to critical operations

Organizations implement preventive maintenance for several reasons – one of them is reducing production disruptions. Since the machinery operates reliably, consistently, and without overheating and malfunctions, there are fewer bottlenecks than before, leading to smoother operations, lower costs, and lower time required for the same processes.

Reduces emergency work requests and repairs

“A stitch in time saves nine” is a famous proverb, and in the case of maintenance, the stitch is preventive maintenance. Since all the pieces of equipment are receiving preventative maintenance, they work efficiently, reliably, and consistently, drastically reducing the need for emergency repairs.

Even with preventive maintenance, repairs and emergency work requests are witnessed. Still, since the machinery receives regular maintenance, it overheats less, experiences fewer malfunctions and breakdowns, and minimizes unplanned downtime, leading to fewer emergency requests. This helps reduce maintenance and repair costs significantly, one of the prominent preventive maintenance benefits.

CloudApper CMMS ensures preventive maintenance benefits

CloudApper CMMS is a robust yet easy-to-use CMMS software that helps organizations achieve preventive maintenance benefits using smartphones. Assets, work orders, work requests, maintenance scheduled, technicians, spare parts, inventory, management, vendors and more can be managed using smartphones – making maintenance management truly mobile. However, these modules and the app itself are highly customizable since it’s built with CloudApper, a no-code enterprise app development platform. Organizations can modify the solution to fit their needs rather than changing their practices to fit the app, making CloudApper CMMS the ideal solution for virtually any organization.

CloudApper CMMS costs only $10/user/month and provides access to a marketplace full of customizable enterprise apps. The possibilities are endless!

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More