Table of Contents

Proactive maintenance plays a crucial role in maintaining production levels, reducing redundant expenses, ensuring worker safety, and utilizing equipment properly. However, many organizations still rely on reactive maintenance, which can be harmful to most modern equipment. Most machinery comes with manuals that explain its maintenance requirements because manufacturers understand how it improves the machinery’s performance and longevity along with the user’s experience. Unfortunately, many organizations don’t understand proactive maintenance and are hesitant to switch from reactive maintenance, whereas the benefits of preventive maintenance far outweigh the costs.

That being said, let’s look at the benefits of preventive maintenance that warrant organizations to make the switch and how a robust maintenance management system helps.

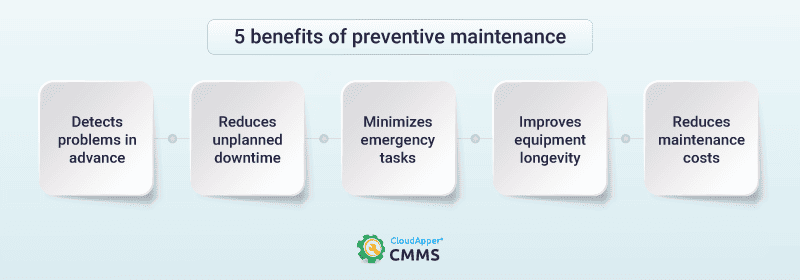

Top 5 benefits of preventive maintenance

Detects potential problems before they happen

Preventive maintenance consists of several activities, one of which is inspecting the equipment. Some of these inspections are thorough and might require technicians to take the equipment apart. However, if conducted using a robust CMMS solution, these inspections can identify underlying symptoms that lead to future malfunctions or unexpected equipment breakdowns. Then, maintenance teams can work on solving the issue, essentially preventing potential malfunctions or breakdowns.

Reduces downtime significantly

One of the most common benefits of preventive maintenance is that it drastically reduces unplanned downtime. Additionally, preventative maintenance ensures that the equipment receives maintenance and thorough inspections regularly, preventing problems from the start. Finally, by doing so, preventive maintenance ensures that the equipment performs reliably without any hiccups.

On the other hand, reactive maintenance focuses on fixes after the equipment malfunctions, leading to increased unplanned downtime, delays, and uncertain timelines as to when technicians will be able to fix them. This shows how preventive maintenance is better as it reduces unplanned downtime by scheduling downtime for preventive maintenance tasks.

Reduces emergency maintenance tasks

Another preventive maintenance benefit is that it reduces emergency work orders. Since the equipment receives maintenance like lubrication, spare parts replacement, and cleaning, it tends to work correctly and fails much less often, leading to fewer emergency work orders.

Sure, emergency work orders and asset repair will always happen as any equipment might fail at any moment. Still, with preventative maintenance, urgent work orders are reduced significantly as the failure rate falls for most equipment.

Improves asset’s life

One of the crucial benefits of preventive maintenance is that it lengthens the asset’s longevity. If a piece of equipment is fixed only after breakdowns, it’ll experience far more wear and tear, leading to more breakdowns and malfunctions. This ultimately hampers the asset’s longevity, performance, and causes premature death.

Preventive maintenance effectively aims to prevent the problems from the start, reducing problems and improving asset longevity.

Reduces maintenance costs

From all of the benefits above, it’s clear that preventive maintenance helps minimize equipment downtime, simplify repairs, schedule maintenance tasks, improve asset longevity, and reduce replacements. As a result, maintenance, replacement, and repair costs are significantly decreased. Moreover, it also helps improve productivity, ensure that production is on track, and reduce costs.

Final words

The benefits of preventive maintenance are many. With a robust and customizable CMMS software solution like CloudApper CMMS, organizations can benefit from improved efficiencies and affordably ensure preventative maintenance, just the way they want to, using their smartphones.

CloudApper CMMS costs $10/user/month, includes access to several enterprise mobile apps. Contact us now.

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More