Table of Contents

Modern organizations have several complexities to deal with every day – production disruptions, bottlenecks, inefficiencies, workplace safety incidents, rising costs, and unplanned downtime, just to name a few. While different problems have different solutions, many of these issues can be traced back to a common factor – offline or malfunctioning equipment. As long as effective equipment maintenance and repairs are ensured, organizations can minimize unplanned downtime, reduce operational costs, improve productivity, extend asset life, reduce workplace safety incidents, and enjoy higher profits. This article will provide some of the most effective ways responsible organizations are simplifying equipment maintenance at their different plants and facilities.

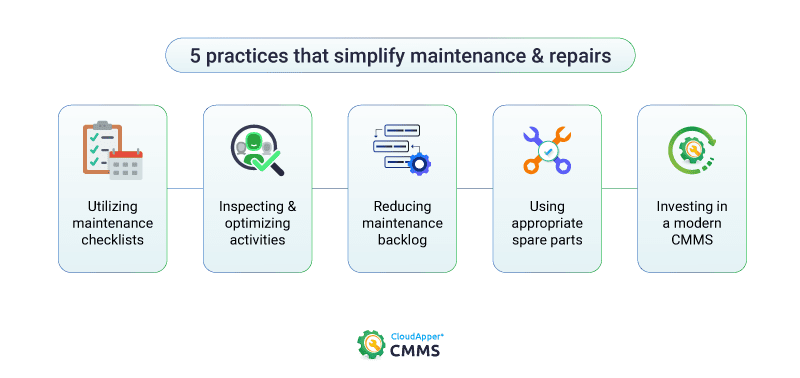

Five practices that simplify equipment maintenance and repairs

Creating and utilizing checklists for maintenance tasks

Maintenance technicians need to work on several different pieces of equipment that require maintenance tasks, inspections, emergency repairs, spare parts replacement, or servicing. Since there are few resources to carry these numerous tasks, quite understandably, maintenance technicians might miss a step or two – they’re only human.

Fortunately, this can be easily remedied with checklists. These checklists include all the steps, activities, and materials required to complete the tasks effectively. Even if the maintenance technician misses out on something, the checklists help ensure that they are following the entire process to the T – simplifying maintenance and repairs in the process.

Inspecting and optimizing activities

Several organizations think that maintenance management is limited to repairing or carrying out maintenance tasks. However, responsible organizations know that maintenance management is much more than that – it’s a continuous process that helps improve existing activities.

Maintenance teams need to inspect current processes and identify whether they are detrimental to the equipment. If so, then the process needs to be optimized in a way that reduces equipment wear and tear. For instance, an industrial centrifuge requires lubrication, but it is used in a way that requires frequent lubrication. However, lubrication is provided long after the equipment needs it – something that can cause friction, overheating, or wear and tear. Maintenance team members need to identify this issue and optimize lubrication management, helping the centrifuge run reliably, extend its life, and ensure smoother operations.

Working on reducing the maintenance backlog

A maintenance backlog is a crucial component of maintenance management, and organizations need to keep it at or under acceptable levels. While the maintenance backlog is usually high with reactive maintenance, preventive maintenance reduces it significantly since there are fewer unexpected equipment breakdowns. However, in some cases, even with preventive maintenance, the maintenance backlog can be higher than anticipated. The maintenance team just needs to allocate resources promptly to reduce the backlog effectively.

For instance, when there are fewer preventive maintenance tasks, inspections, or emergency repairs at hand, the maintenance manager can work on reducing the maintenance backlog that has been piling up. With a robust maintenance management system like CloudApper CMMS, maintenance managers can reduce the backlog by creating work orders and assigning technicians to the tasks. Beforehand, they can also prioritize tasks so that the most important ones are carried out first.

Using appropriate spare parts and inventory

While cost-saving is always an objective of any given organization, doing so by buying cheaper spare parts or lubricants is the wrong way to do it. These cheaper components can lead to performance degradation, lower reliability, and might ultimately cause malfunctions within the equipment. As a result, instead of reducing costs, organizations might end up incurring higher maintenance, replacement, and repair costs.

On the other hand, while components such as high-quality lubricants or original equipment manufacturer (OEM) spare parts might be costly, they ensure better performance, improve reliability, and meet the equipment’s requirements. In fact, many spare parts even come with a warranty and dedicated support to give that peace of mind to the organization. While not all spare parts are created by the OEM, the documentation that comes with the machinery typically includes a list of manufacturers they recommend – going with any of those, especially after checking reviews, can reduce the amount of equipment maintenance and repairs required.

Investing in a CMMS that simplifies maintenance and repairs

While the above were a few ways organizations simplify equipment maintenance, maintenance management actually comes down to the maintenance approach and CMMS software used. The maintenance management system used can either make or break equipment maintenance at your facility.

While there are several CMMS solutions out there, organizations need to use an affordable one – they don’t have an unlimited maintenance budget. In many CMMS solutions, many features are hidden behind more expensive subscription packages. Moreover, organizations need to choose a solution that they can customize to meet their maintenance needs rather than changing their practices to fit the CMMS. Also, since virtually everyone has powerful smartphones and tablets nowadays, organizations need to choose a solution that can be used anywhere using these portable devices.

Fortunately, CloudApper CMMS checks all the right boxes, and more!

CloudApper CMMS provides all the necessary features like asset management, spare parts management, vendor management, technician management, maintenance scheduling, an analytics dashboard, and more. All of these modules are highly customizable – you can add ones you need and remove the unnecessary ones, making CloudApper CMMS truly your own. One of the best parts is that it can be used from smartphones, ensuring that your maintenance management team can work on the go. All of this, and more, costs only $10/user/month – making it one of the most affordable CMMS solutions out there.

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More